Engineering (and selling) the elusive fuel cell, Plus: Course shopping drives grade inflation :: Chemist battles terror, in the lab and at the scene

ENGINEERING (AND SELLING) THE ELUSIVE FUEL CELL

fUEL CELLS PROMISE A HOST OF BENEFITS: High-efficiency conversion of fuel to electricity, low emissions, and virtually silent operation. So why haven't they replaced internal combustion engines in automobiles and your local coal-burning power plant? It turns out that getting a cost-effective fuel cell from concept to market is a lot more complicated than Welsh gentleman-scientist Sir William Grove anticipated when he built the first one in the mid-1800s. With cheap fossil fuels readily available for much of the last century, incentives to refine alternative technologies have been few and far between but with increasing demand for clean, efficient, domestically produced power, that's all changing.

The basics of fuel cells are simple. Unlike a combustion engine, which generates power by burning fuel to create mechanical energy to spin the turbines in an electrical plant (or animate the gears and shafts in a vehicle), fuel cells convert the chemical energy trapped in such sources as hydrogen directly into electricity. Most fuel cells rely not on pure hydrogen gas, but a source— fossil fuels, methane, even ammonia—with the element embedded in more complex molecules. A component of the fuel cell known as the reformer liberates the electrons from the hydrogen atoms for use in the cell.

Among the problems with fuel cell technology, says Newman professor of physical science Frank DiSalvo, who co-directs the forty-researcher Cornell Fuel Cell Institute, is that the chemical process that frees the hydrogen can corrode the cell's components and inhibit the action of the catalysts in a process known as "poisoning." DiSalvo's lab—which investigates poisoning-resistant materials known as ordered-intermetallic compounds—focuses on low-temperature fuel cells, the type perhaps best suited for replacing an automobile's gas engine. "It's not often you can see such a close link between the basic research and a potential payoff," says the professor, who got hooked on fuel cells when he attended a PhD defense with CFCI co-director Héctor Abruña that suggested a theoretical solution to the problems associated with platinum catalysts.

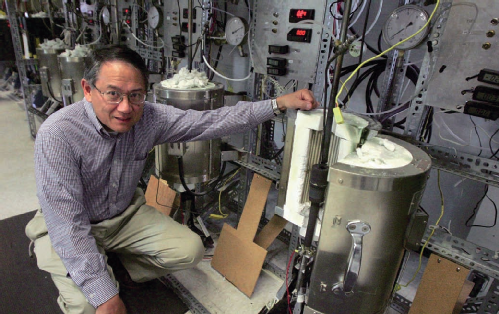

The potential of fuel cells—and the possibility of overcoming their challenges—captured the imagination of entrepreneur and former Cornell trustee Benson Lee '63, BEE '64, in the late Eighties. Then on hiatus after launching Biolectron, a successful bone-healing technology, he was searching for a new venture when— over drinks at the Statler—a fellow trustee mentioned that a Cleveland firm was looking for a buyer for its high-temperature solid oxide fuel cell technology. (The technology is appropriate for continuous-operation applications like power generation, but ill-suited for the intermittent demands made by vehicles.) By 1990, Lee was in on the game. He formed a new company, hired a team of engineers, and charged them with refining the technology to fill a market niche: affordable 1 kilowatt cells engineered to run on a range of fuel types from propane to methane to kerosene, lightweight and compact enough to ship by FedEx, and possible for a lay person to operate and maintain without special tools or equipment.

To get around the poisoning problem, the engineers at Lee's Technology Management Inc. have focused on sulfur tolerance, which means their cell can run on a host of fuels that poison most others. The next hurdle: further reducing the size and cost of each unit and extending their field testing. But for Lee, such challenges are only part of what makes fuel cells a compelling business proposition. While NASA has used liquid hydrogen-powered fuel cells in the space program since the Sixties, and the military is interested enough to fund research, the public hasn't exactly been clamoring for fuel cells on the shelves of their local Best Buy. That meant the company had to get creative, and Lee assigns three books on entrepreneurship to each scientist he hires. The required reading explores the challenges of marketing what's known as disruptive technology—a product without a market niche, like the first telephone, the first PC, or the Internet. As Henry Ford once famously said, "If I'd asked my customers what they wanted, they would have asked for a faster horse." Lee thinks of the entrepreneur's job as creating value by making connections that aren't obvious, and it's a role he relishes. "You start with the technology first," he says, "and think critically about who would be the right customers to match up with it."

'You start with the technology first,' says Lee, 'and think critically about who would be the right customers to match up with it.'To optimize that matchmaking, Lee adopted a hub-and-spoke model, with the fuel cell at the center, and started cultivating contacts—with military contractors interested in a silent, portable power source for communications equipment; with the USDA and commercial agribusiness to convert vegetable oil and the biogas byproducts of livestock operations into cheap power; and with the nation's two largest truck manufacturers to give long-haul semis high-efficiency power for heat and refrigeration while complying with strict anti-idling laws. "Using a fuel cell instead of idling a main truck engine can save 1,300 gallons of diesel per year per truck," says Lee, "which means that in terms of dollar justification on fuel savings alone, we're at $3,900 annually." Another of Lee's spokes targets philanthropic groups dedicated to rural development. A compact, portable fuel cell could provide electricity to power schools, health clinics, and water treatment facilities, using whatever liquid or gaseous fuel happens to be available, including methane captured from human and livestock waste.

So far, Lee's engineers have demonstrated that his technology can run on gas and liquid fuels, including propane, jet fuel, ammonia, ethanol, biodiesel, and used cooking oil, among other sources. This fall, the company demonstrated a fuel cell at the Ohio State University Farm Science Review that's powered by oil from soybeans, the state's largest cash crop. "If fuel cells were available across the Midwest's farm belt," he says, "they could enable America's small farmers to play a direct role in reducing our nation's dependency on foreign oil and consumption of fossil fuel." At the moment, however, Lee has to overcome a more immediate challenge—drumming up funding for the robust field tests that will prove his engineers have crafted a reliable system. "We have to get through the 'Valley of Death,' where you're past the hard-core R&D that the government likes to pay for, but not quite to where a big corporate player can make and sell it," he says. "Because so many companies in the fuel cell industry have overpromised and underdelivered, it's gotten tough to convince people we're legitimate. It takes some creative financing to keep plowing through before you run out of food and water."

— Sharon Tregaskis '95

Gut Check

COURSE SHOPPING DRIVES GRADE INFLATION

aSSISTANT PROFESSOR TALIA BAR was leaving her intermediate economics class one day in 2003 when a group of undergrads asked what the median grade would be. Probably a C+ or B-, Bar replied. "The students were shocked," she remembers. "Immediately a large group gathered around me and said there had never been such a low median grade in this class. I said, 'How do you know?' They told me, 'It's online.' "

aSSISTANT PROFESSOR TALIA BAR was leaving her intermediate economics class one day in 2003 when a group of undergrads asked what the median grade would be. Probably a C+ or B-, Bar replied. "The students were shocked," she remembers. "Immediately a large group gathered around me and said there had never been such a low median grade in this class. I said, 'How do you know?' They told me, 'It's online.' "

This interaction prompted Bar and two Cornell colleagues to study an experiment taking place in their own backyard: the University's 1996 decision to publish median grades of undergrad courses both online and on student transcripts. The policy began as a noble attempt to give students a better idea of their performance and make letter grades "more meaningful," according to the Faculty Senate's resolution. The Senate also reasoned, perhaps naively, that "more accurate recognition of performance may encourage students to take courses in which the median grade is relatively low." But the move seems to have backfired.

Twelve years later, median grades are still not on transcripts, due to software problems. But online postings (under "Useful Links" at http://registrar.sas.cornell.edu/) have prompted students to shop for "gut" courses and more than doubled the rate of grade inflation, according to a new paper by Bar and her colleagues. The Atlantic Monthly cited their work when it called Cornell's grade reporting policy "a case study in how to pump up GPAs." As an economist, Bar was not surprised at the paper's findings. "I know that people respond to incentives," she says."And the policy allowed students to act on an incentive."

The professors crunched 800,000 data points collected by the Office of the Registrar, analyzing the records of Arts and Sciences undergraduates enrolled between 1990 and 2004. They found that after the policy went into effect in 1998, the rate at which grades rose more than doubled, compared to 1990-97. And the median-grade Web page got more than twice as many hits during pre-enrollment periods—precisely when students are most likely to need grade information to choose courses. They also discovered that students with lower SAT scores were more likely to enroll in leniently graded classes.

Overall, marks in the college rose 6.5 percent, from slightly higher than a B in 1990 to a B+ in 2004. That may not seem like much of a jump, says co-author Asaf Zussman, associate professor of economics, but in fact it's substantial. "The important point to remember is that grades are bounded from above by A+," he says. "As grades go up there is less and less room for further increases." And while conventional wisdom blames inflation on instructors grading more leniently, the authors calculate that student shopping accounts for about 60 percent of the increase in Arts college grades since 1998. "This is a very rough estimate," Zussman says. "Nevertheless, we are confident that the contribution of 'shopping' is substantial." The study, "Quest for Knowledge and Pursuit of Grades," is being considered for publication by a peer-reviewed economics journal. In the meantime, the Social Science Research Network has published it on its website (www.ssrn.com).

Students may have some incentive to change their shopping habits soon, however. Twelve years after the Senate's resolution, the Office of the Registrar finally has a record system able to print median grades on transcripts, says David Yeh, assistant vice president for student and academic services. The grades will appear for courses taken in Fall 2008—though only for freshmen and the classes that follow. But the fact remains that a higher GPA is its own reward, and potential employers or financial-aid officers will not necessarily consult transcripts to put grades into context. Nonetheless, the policy puts Cornell ahead of its Ivy League peers in terms of transparency, says coauthor Vrinda Kadiyali, associate professor of marketing. "We're saying, 'This is the grade, and this is how it compares to the others.' That's a concerted effort to show where the student stands. Holding ourselves to a higher standard than our peers, and communicating it clearly, is definitely an improvement."

— Susan Kelley

Bombs Away

CHEMIST BATTLES TERROR, IN THE LAB AND AT THE SCENE

oN THE GROUNDS OF THE MARINE Corps base in Quantico, Virginia— through two checkpoints, down a road that runs past a rifle range and the Drug Enforcement Administration's training academy—is a building that would drive any "CSI" fan mad with desire. With its long walls of glass and ventilation pipes protruding from the roof, the sleek facility looks like the R&D headquarters of a major pharmaceutical company. But it's the FBI Laboratory, a 500,000-square-foot building that houses some of the world's foremost forensics experts—authorities in everything from fingerprints to ballistics, handwriting to DNA. There are specialists in facial imaging, hairs and fibers, document forgery. One of the lab's databases contains 11,000 examples of shoe soles that can be matched to footprints at crime scenes; another has every type of auto paint ever made.

Chemist Kirk Yeager, PhD '93, has been at the lab since 2000. But he would-n't particularly appreciate the "CSI" reference; Yeager, like many of his colleagues, deplores what's known as the "'CSI' effect": jurors' increasing desire to have forensic evidence tied up neatly with a bow. " 'CSI' glamorizes forensics to the point of making it unrealistic," he says. "The show is actually a detriment to our job. There are no magic machines that identify something in short order. There's a lot more interpretation that goes on in forensic examination, and not that kind of surety. It's trying to put together pieces of a puzzle and make the most logical inference. I have had to fight 'CSI' to try to get people to understand the real science behind forensics."

As a senior forensic examiner in the Explosives Unit, Yeager investigates bombings in the U.S. and around the world. (He's not, as he puts it, "on the sworn side of the house"—an agent who carries a gun and makes arrests.) On hours' notice, he has traveled to bombing sites in Beirut, the Gaza Strip, Indonesia, South Africa, Morocco, and more; he investigated the Bali nightclub bombings and the terrorist attack on the USS Cole. Domestically, he has worked on such cases as a college student who blew himself up outside a University of Oklahoma football game and the downing of United 93 on September 11. "When a bomb goes off, it's my unit that goes out," he says. "We pick up the pieces, catalogue them, bring them back, and examine them. We try to figure out what the bomb was, how it functioned, where the components came from."

Yeager, who's married with two children, spends about half his time on the road—visiting crime scenes, testifying in court, speaking at conferences, and training first-responders and law-enforcement agencies in the techniques of post-blast investigation. A leading authority on peroxide-based explosives, he keeps an eye on the latest terrorist trends; last winter, the Associated Press did a story on his work with so-called "Mother of Satan" bombs made from ingredients found under the kitchen sink. He's on call 24/7, fielding inquiries from federal agencies and offering his expertise to local police. "Technology changes, and you've got to keep up with that," he says. "But what's keeping us most busy right now is taking a proactive stance. I get phone calls saying, 'We have intercepts, we have this information. What can these people do? How do they pose a threat?' Since 9/11, the FBI has been heavily involved in prevention, which means you have to look at a whole pantheon of threats that are not real, and some that are very real, and do a lot of analysis along the way."

When he was studying inorganic chemistry on the Hill, Yeager hardly thought he'd end up at the FBI; he figured on a teaching career. But after earning his PhD under Professor James Burlitch, he went on to a postdoc at the New Mexico Institute of Mining and Technology, which has a specialty in energetic materials—a.k.a. explosives—eventually becoming the program's associate director before joining the FBI. Burlitch, now a professor emeritus, remembers Yeager for his scientific talent—and for blasting heavy metal music, wearing offbeat clothes, and enthusiastically decorating the lab for Halloween. "It's good that somebody is doing this hard stuff," Burlitch says of Yeager's work at the intersection of chemistry and law enforcement, "because most of us wouldn't be inclined to."

Part of Yeager's job includes re-creating bombs, even setting them off on a Marine Corps demolition range. (And, yes, he does have his own body armor.) He and his team also make facsimiles of the devices for presentation in court; one room at the lab houses an informal museum displaying, among other things, Unabomber devices, a mock-up of the Centennial Olympic Park bomb from the 1996 Atlanta Games, and an oversized model of the shoe bomb worn by Richard Reid when he tried to take down a transatlantic flight. "I don't want to sound corny, but the thing that drives me the most is actually making a contribution and a difference," Yeager says. "Through my research and experience with explosives, I can get information out to help people, from first responders—firefighters, EMTs, police on the ground—all the way up to an international level."

— Beth Saulnier